As a leading manufacturer in China's phone battery industry, Huidafa (DEJI) have always adhered to the belief that quality first, customer first. Because of the continuous improvement of battery quality requirements, we are becoming more and more convinced that only good quality can enable us and our customers to achieve a win-win situation.

Below I will introduce to you how we control the quality of the phone battery:

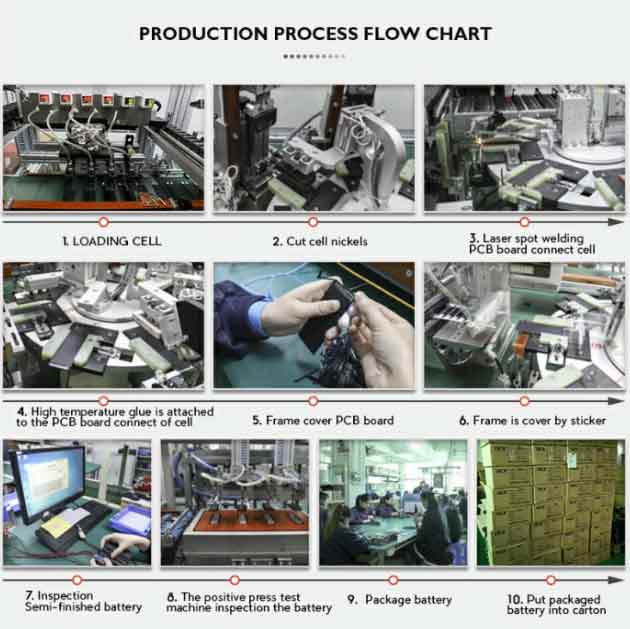

1.all the cell(Raw material) will check the capacity in grading system and to make sure all the batteries with full capacity.

2.100% checked the PCB function(charging,discharging,over-discharge) before production.

3.Cut the nickel, because different model with different size nickel, so need to cut the nickel before laser printing.

4.We use new technical machine (Laser spot welding ) to connect the nickel with PCB board, it can make the batteries more strong and not easy to separate, the battery quality will more stable with the strong connection.

5.Sticker the high-temperature glue protect the PCB, to avoid the batteries effect by the human body static, so the worker must wear the Antic-static bracelet.

6.Cover the frame on both side of the batteries. Our factory open the mould with frame, different model with different size frame.

7.Semi-finished products 100% testing , we use integrated testing machine to test the batteries voltage,charging current, internal resistance,etc.

8.Sticker the insulation paper to fix the PCB head, to make it more strong connecting.

9.QC checking again after sticker the labels with phone batteries.

10.Final QC 100% checking before delivery out the batteries, make sure it with 100% tested QC checking.

Full Automatic machine to attach the labels, IPhone4,4s,5,5s with full packed by the machine, other model with a half packed.

Printing machine, it can print the model number and production date on the outside of the box.

Packaging machine, put the battery and blister inside the packaging, the machine will press down with high temperature , because the packaging with glue on round , the machine can make the packaging close together.

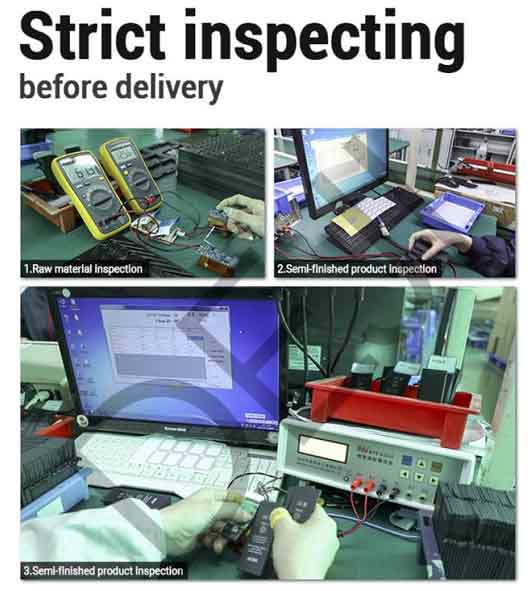

Below is our strictly quality control details:

1.For phone battery cell, we use real & full capacity new phone battery, our PCM and PCB board are also with good quality. Our IC use imported IC.

Our PCB board make the circuit stability be better than the public PCB board.

2.Our phone battery passed over-charge, over-discharge, over-current,short-circuit, over-temperature etc 5 protection functions.Battery cell could also protect itself. To make sure they are safe and of high quality.

3.We make mobile phone battery for 17 years.We are 17 years professional mobile phone battery factory, Alibaba 8 years Golden Supplier.

4.Battery are dangerous and sensitive goods. Safety is very important, we have safety and quality guarantee.We have strict QC team. Battery are all 100% inspected before shipment.Warranty is 1 year.

5.We have good after-sale service Or Replacements policy. Battery are with good quality. Basically no battery returns from abroad. So you could relax about the after-sale service.

Dear friend, We are very professional phone battery factory, we do mobile phone battery for 16 years and do power bank for 7 years. have two factories, with 7 production lines and automatic production lines.

Our daily production is 10,000pcs power bank and 20,000pcs mobile phone battery.

Our monthly production is 300,000pcs power bank and 600,000pcs mobile phone battery.

OEM & ODM order are all welcomed, Warmly welcome to visit our factory Huidafa (DEJI) at any time.

sales@batterydeji.com

sales@batterydeji.com