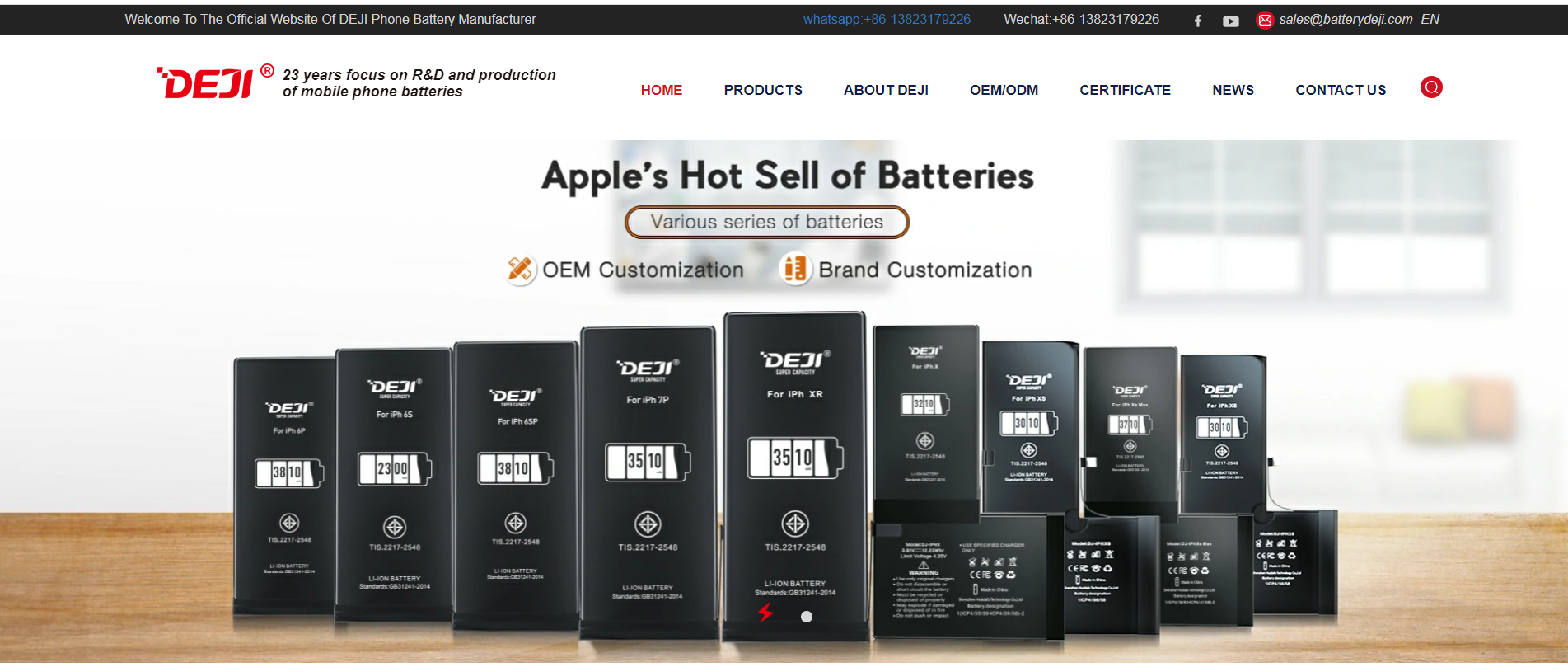

1.DEJI Image: DEJI batteries for iPhone and Samsung are salable and have a good public praise in domestic market as well as overseas market. Now,we are paying a visit to the factory, so as to investigate how DEJI batteries were made.

2.Strictly Quality Control:

Before entering the workshop ,we are coming to this room called capacity cycle test lab. All of DEJI batteries have to go through the capacity cycle test before entering the stream lines.

We can see that our workshop is not only very spacious and bright ,but also very clean and tidy. Furthermore, the state of our staff is very energetic.

As far as we know, DEJI is a real productive manufacturer with the most advanced production process . It adopts a series of complete automatic production lines which is second to none in the whole phone battery industry.

DEJI has a senior professional technical team. And the key raw material are all imported from famous corporations. Therefore, it guarantees the quality of products from three aspects: equipment, technology and raw materials.

That makes the battery can still remain 95% of initial capacity after 500 cycles and it can last up to three years.

Installment of built-in battery is also very convenient, we have detailed installation instruction and disassembling video in the attachment of our products for your replacement.

All the material (PCB and battery cell) are 100% tested before producing. We use the original capacity and higher capacity battery cell ,Imported American TI design original IC and the stable and good quality special PCBwhich is designed by our boss Jackie and our professional engineers. All the semi-finished and finished products are 100% tested, through 3 parts strict testing and make sure 100% good quality before delivery.

Our factory has passed ISO9001 and iphone batteries got the CE FCC ROHS, PSE,KC,TIS;certificates and also can provide the MSDS,UN38.3 for shipping.

OK, that is the preliminary understanding of DEJI batteries, Thanks!

3.Extra special procedure: molds and fixtures for the folded flex cable &final Terminal.

They fold flex cable &final Terminal into the final shape which battery be assembled into iphone.

The flex cable and the final Terminal is hard to fold which need Skilled technicians to operate.

Fold the PCB with flex cable,which make the battery be more easily to be assembled into iphone smartphone.

Our engineers opened the molds and fixtures for the folded flex cable &final Terminal.

sales@batterydeji.com

sales@batterydeji.com